By Jay Ferguson, Louisville Water Museum Education Specialist

By Jay Ferguson, Louisville Water Museum Education Specialist

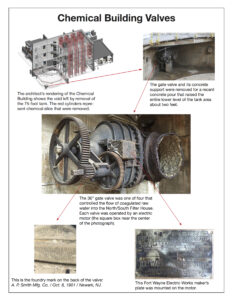

The Chemical Building at the Crescent Hill Water Treatment Plant is midway through just the first phase of a multi-year renovation that will convert space for use as offices and storage. This phase includes new concrete that raises the floor about two feet in the area that once housed a 50-foot-wide and 75-foot-tall tank.

Scheduled to be finished by the end of the year, the first phase also will include two new stair towers and the relocation of plant services.

The renovation is the latest chapter in the story of a critical Louisville Water facility—a story that began over a century ago.

Overcoming Initial Challenges

The massive and unprecedented undertaking of building the Crescent Hill plant took a decade to complete. It had to be built from the bottom up and used new technology. Charles Hermany, Louisville Water’s chief engineer from 1861 to 1908, designed the plant based on findings from groundbreaking filtration tests that sanitary engineer George Warren Fuller conducted in the 1890s.

Optimism abounded at the turn of the century. In 1899, it was thought a clear water basin would be completed by the end of the year and filters installed in 1901, but the clear well still was not complete at the end of 1900. This, along with problems with contractors, set back the rest of the work for years to come.

The Courier-Journal kept the public updated on the progress of the plant. In November 1905, the newspaper ran an article that said the “public has been impatiently awaiting the day when it shall begin receiving the benefits of the great improvement ….”

Still, the reporter called the work on the plant “stupendous.” He noted that a train car load of pump parts was lost in transit and concluded that “considering the vast magnitude and importance of our filter system and plant, and this company being the pioneer in a work of the character, it is next to impossible to control every contractor and have every contract promptly completed ….”

The filters still were not finished when the pumping station started operation in 1907, and Charles Hermany was nearing death. In fact, he died on the day of the first filter trials the next year. The filter plant finally went into operation on July 13, 1909.

The Importance of Valves

Hermany’s designs for the filter plant included backup plans for an uninterrupted supply of water into the city. Gate valves were installed outside the plant to completely by-pass the filter house in time of need.

This happened in the first year of operation on a couple of occasions when the Oak Street 48-inch supply main ruptured, and the water had to be diverted into the older 36-inch main going down Frankfort Avenue. According to a journal from the period, on one occasion—December 22, 1909—“coagulated, unfiltered water ran in the 36” main to the city.” (Our scientists and engineers would never even think of doing that again.)

Inside the Chemical Building, massive 36-inch gate valves controlled the coagulated raw water going into the North/South Filter House. Hermany knew these valves would be opened and closed often. In the bidding document, he wrote it is of “great importance that these valves be operated by the simplest and quickest devices…,” and he specified the use of electric motors.

The valve shown in the image below controlled water directly from the 75-foot coagulation tank, which was modified to be a wash water tank for filters after coagulation basins were built.

A few years ago, Louisville Water’s Historic Assets Team photographically documented assets in the Chemical Building before their removal. The brass maker’s plate from the pictured valve is now part of Louisville Water’s historical collections. The valve itself was much too large to save.

Phase two of the current renovation of the facility will focus on the upper floors in the area that housed the massive tank. The projected completion date for the second phase is the end of 2022. Phase three, which will include completion of new office areas as well as renovations in the lab area, is scheduled to be finished in 2024.